Paul and Keith Operating During

Winterfest At

Maricopa Live Steamers

Operation Meet 1/18, thru 1/22, 2023

*****************************************************************

After arriving at the Maricopa Live Steamers (MLS)our first task was to get out Keith's Locomotive and cars. They are stored in a container that has 7.5" gauge track inside on 3 levels. Keith shares the container with 2 other members so their equipment is also inside the container.

To reach Keith's locomotive we had to remove a train, seen here on the second level, then Keith crawled back into pull out his loco.

We moved all the cars and locomotives using a lift that club has on rails to access containers.

These lifts allow the access to all levels of the containers and access to tracks that lead to engine facilities.

We also used the lift to get out Keith's gondolas seen on the top level. After adding seats that Keith constructed we had a small train that each of us could ride on and test the loco and cars.

An important note is that the loco had had repairs made last summer and a wired remote control replaced the wireless system that failed last winter. This required testing and becoming accustomed to the new controls.

The area of MLS operations covers acres of the local desert.

Where do we go? I ask Keith as we pulled out pasted the tower into a vast empty space.

That way was the reply and off we went.

We found track running around the area with sidings, crossovers, and crossings. Signals on single track warned us of trains coming our way allowing us to take a siding. Crossings had flashing red lights indicating Stop and look for other trains before crossing.

It turned out that Keith's knowledge of the layout of MLS allowed us to take a long ride on a loop that was double track near the tower but went off into a big loop to bring us back on the track next to us.

Things did not go as well as we would have liked. The throttle was very sensitive and used a center detent as stop. Passing the detent put the train is reverse. Another issue with the loco was that as we ran along at 5 MPH the speed limit the shaking of the train would cause the loco to hesitate and then jump back to speed for no apparent reason. Track had some ballast in the turnouts that needed cleaning and that dirt would derail the light weight cars, even with each of us riding. That meant stopped and rerailed the car by lifting and setting the trucks (wheels) back on the track. We would then clean out the frogs and rail guards so others would not derail.

Upon returning to the tower we were switched into a service area with a clear view of the yards, where members were setting up cars for spotting out on the tracks of the next few days operations. We removed the hoods of the locomotive and started checking the system to determine why the loco was operating as it had.

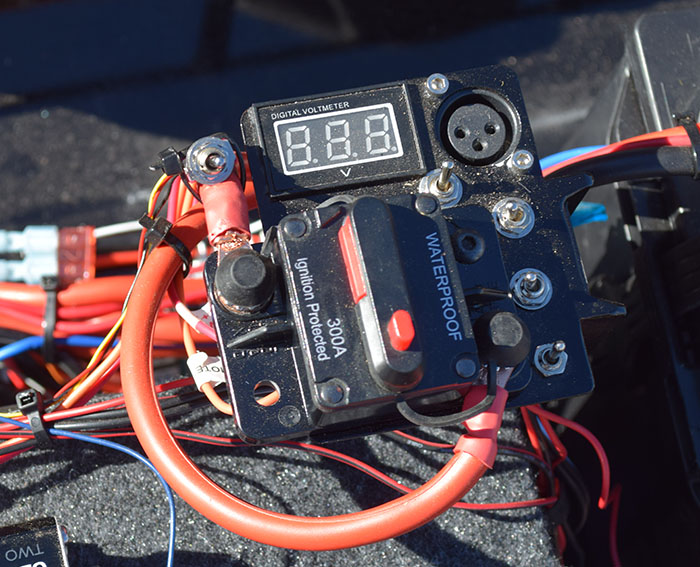

After shutting off the breaker to remove the power from the 4, 12 volt batteries by pressing the red button, making it safe for us to go into the controls.

We checked the wires from the control socket to the locomotive system.

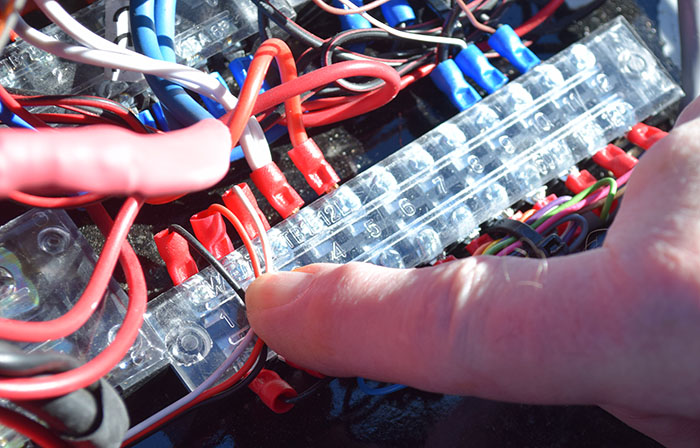

That black wire is the ground for the control box, and it looked a little out of place.

We found that while the screw was tight the spade lug that connects the wire was under the connector and would shake loose. Placing the wire into the proper location and tightening the screw solved our problem with the hesitation caused by loss of the control system ground.

With the control system repaired and tested we switched the lovomotive into a charging track, hooked up the battery charger, and headed off to dinner.

*****************************************************************

THe next morning,Thursday, we were asigned a train and headed out to deliver cars to assigned locations and pickup cars ready to be taken to the yard.

When we got to a town the entirs crew would look over the location of switches and determin how we would place the cars and pick up any that were ready to return.

When we finished our run we returned to the yard with a new set of cars picked up along the way and waited for instructions, by radio as to when and where to enter the yard. We were not alone as other trains for different divisions of the layout were also coming back. We did try to return by noon as the Yard shut down for lunch, which was served in the club office.

At the end of each day we would park the Locomotive and our riding cars at the charging track to be ready for the next day.

By 3:00 PM MST on Saturday, the operating session was over and we turned our loco and cars off the tracks via a turntable until all were put away.

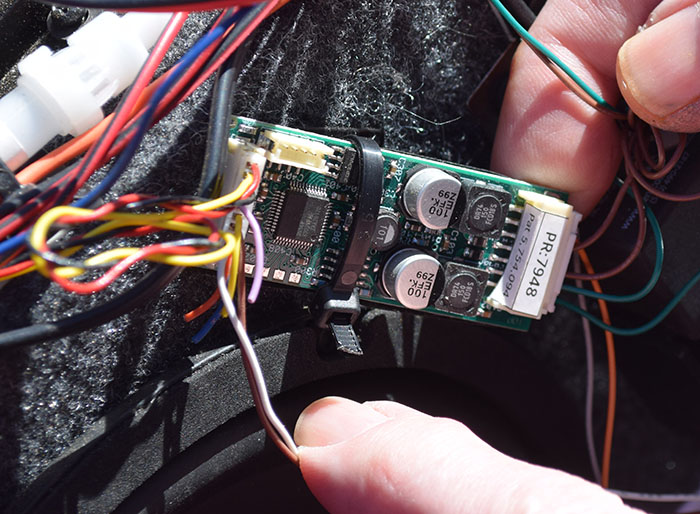

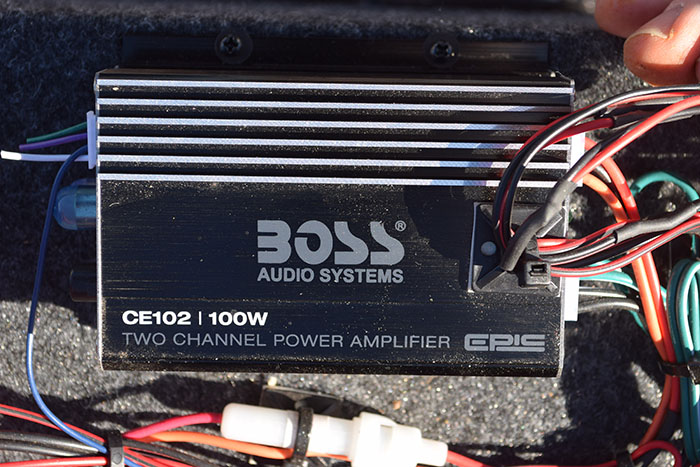

We took the time to photograph the inside of the locomotive and check all the wires. The photos allowed us to locate the on line manuals for the control system and the sound system so we can adjust levels and make the controls a little smoother.

Sound control

Sound Amplifier

Main Power control with a colling fan. Finger points to the input wires, the heavy wires in the back carry the current to the motors.